Refrigerated trailer leasing has never been easier. With lease options from one to ten years available for refrigerated trailer equipment of all specs and design - including your unique configuration - PLM maximizes fleet flexibility. Developing a plan around your goals is what PLM does best, managing to key metrics that define success for your fleet. Leasing provides the financial support to execute your fleet strategy:

Why Lease?

- Walk-away lease options for known replacement plan.

- Short-term equipment to fill seasonal fleet gaps.

- Full maintenance service for all or only locations in need of additional coverage.

- Web-based management tools for fleet visibility across all locations.

And the PLM Fleet Expert Consulting Team provides comprehensive fleet reviews including benchmarking against 15,000 trailers with additional analytic resources for special projects unique to your fleet operations.

The PLM Personalized Customer Solutions team is available to all customers to create custom opportunity assessments of your fleet - identifying cost savings and efficiencies from trailer design to disposition and everything along the lifecycle. The team uses Power BI reporting tools to share their analysis with your fleet team and provide ongoing management through the PLM suite of web-based tools.

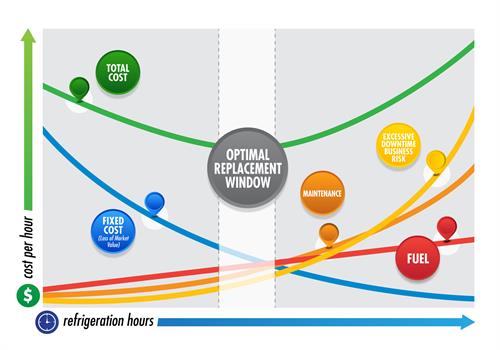

PLM's strategic planning team takes a consumption-based approach for effective refrigerated fleet management and optimized replacement planning.

Not convinced that PLM should be your Refrigerated Fleet Partner? Try us out. Have one of our dedicated Fleet Expert Consulting team members run a complimentary lease versus ownership model on your fleet.

Meet the Team

Chris Yeats-Edwards, Customer Analytics Manager

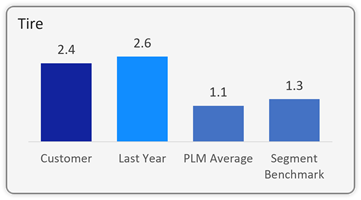

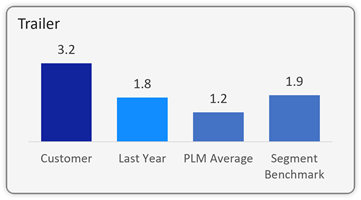

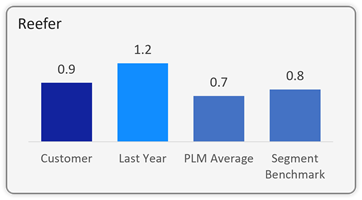

My background in management accounting has given me the opportunity to find customer efficiencies in operations through analysis, insights, modeling and reports. As a key member of the Personalized Customer Solutions Team (PCS), I interact with both the sales team and the customer through conference calls and site visits to integrate PLM's solutions into their processes and save them time and money. We can run their fleet against benchmark data to identify competencies and improve inefficiencies as in the case study below.

Fleet Planning Analysis Case Study.jpg?sfvrsn=18d6f07d_2&Width=550&Height=250&ScaleUp=false&Quality=High&Method=CropCropArguments&Signature=1B52C3C9E431C852ED312BD61622288084146CCB)

Fleet Planning Analysis: Customer wanted to evaluate the optimal life cycle of its fleet, based on usage, maintenance spend, lease payments, and warranties with the goal to reduce total fleet costs by 10%.

PLM Solution: Through segment benchmarking and scenario testing, it was determined a shorter replacement cycle would reduce downtime and maintenance expense that exceeded increased fixed costs in the fleet. Through tightly managed replacement strategies, the fleet achieved 13.7% cost reduction with an astounding 68% decrease in downtime.

Download PLM's Full Capabilities brochure to learn how PLM can support your fleet management!

PLM's Cold Chain Fleet Solutions

Download our brochure to learn how PLM's solutions can fit your needs in rental, leasing, and maintenance of your fleet.

.png?sfvrsn=d36df77d_0)